Services

Turning, milling, barrelling, slotting and much more.

CMS manufactures mechanical components for the B2B market and processes various kinds of materials: plastic, steel, alloy steel, stainless steel and titanium, all with high precision. We also offer bronze, brass and aluminium processing. But what is it that really sets us apart? Our customised lean production model, industry 4.0 technology, customer service and consulting assistance.

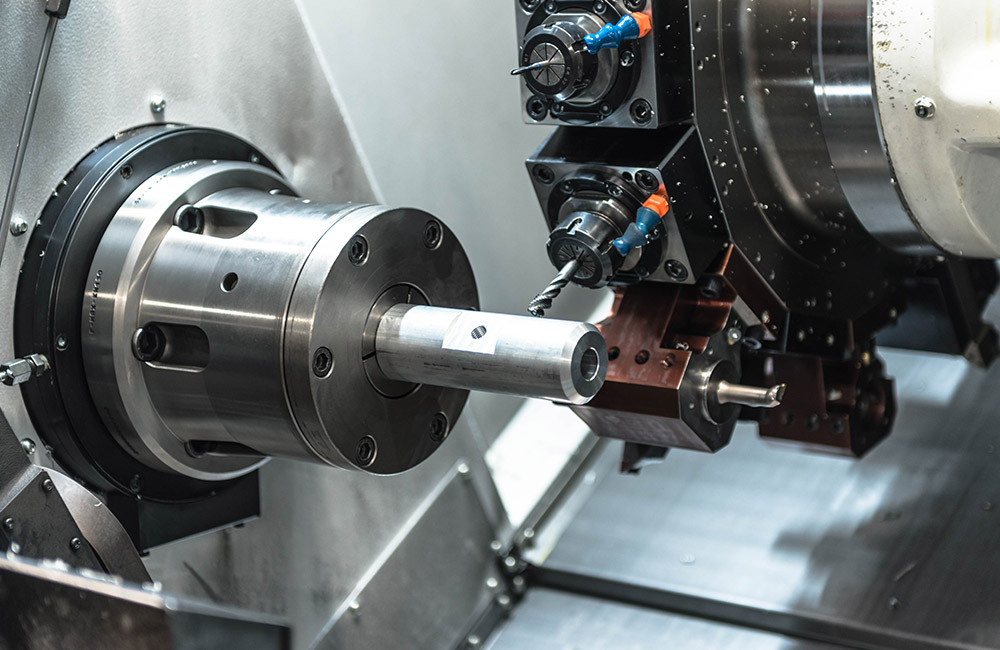

Internal mechanical processing

Turning

CMS employs five numerically controlled machines capable of turning mechanical components, with diameters going from 3 mm up to a maximum of 400 mm, as well as a maximum length of 700 mm.

Milling

Our artisans also handle milling, with three numerically controlled work centres ideally suited to processing various materials and a maximum working range of 700 x 1600 x 700 mm.

Barrelling

Slotting

Other mechanical processes

IN COLLABORATION WITH QUALIFIED OUTSIDE COMPANIES

– Laser engraving

– Laser cutting

– Adjustments

– Electrical Discharge Machining (EDM)

Surface treatments

IN COLLABORATION WITH QUALIFIED OUTSIDE COMPANIES

– Anodising

– Burnishing

– Galvanising

– Chrome plating

– Quenching

We deliver the finished, ready to be used products directly to our clients upon completion.

Industry 4.0 technology:

all under control.

NEW

Our machines are configured and interlinked via tablet to the company’s operating system. We can guarantee timely operational control and provide immediate feedback on the ongoing progress of a commission, all in real time.

Monitoring

Punctuality

Transparency

Planning

Industries

We manufacture components for machinery used in various industries.

Food

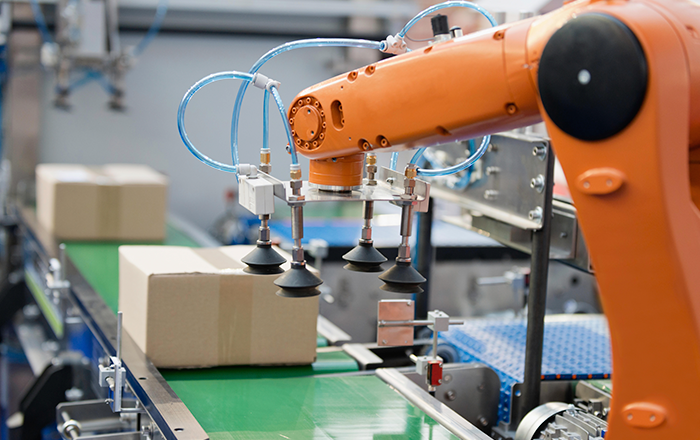

Packaging

Lighting

Jewellery

Oil hydraulics

Healthcare

Glassware

Optics

Textiles

Heating

Moulding