Custom-made

From design to finished product.

The true strength of CMS lies in our ability to customise and optimise production, which goes from taking on a client’s design all the way to creating a genuinely custom-made part, including any and all surface treatments. From rough outline to finished product, we will guide you step by step through the process with which we shape all-new, all-different stories, united by a common purpose: achieving a greatness that is distinctly Made in Italy.

1 - Outline view

The client presents their design and shares their initial project, for which we provide direct technical consulting and create a quote. There is then a final consultation, followed by project establishment and approval.

2 - Production process study

Our technicians carefully analyse our client’s request and calculate the necessary work requirements, to ensure lean production and constant monitoring.

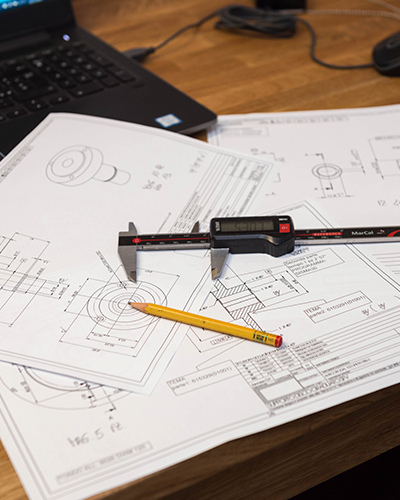

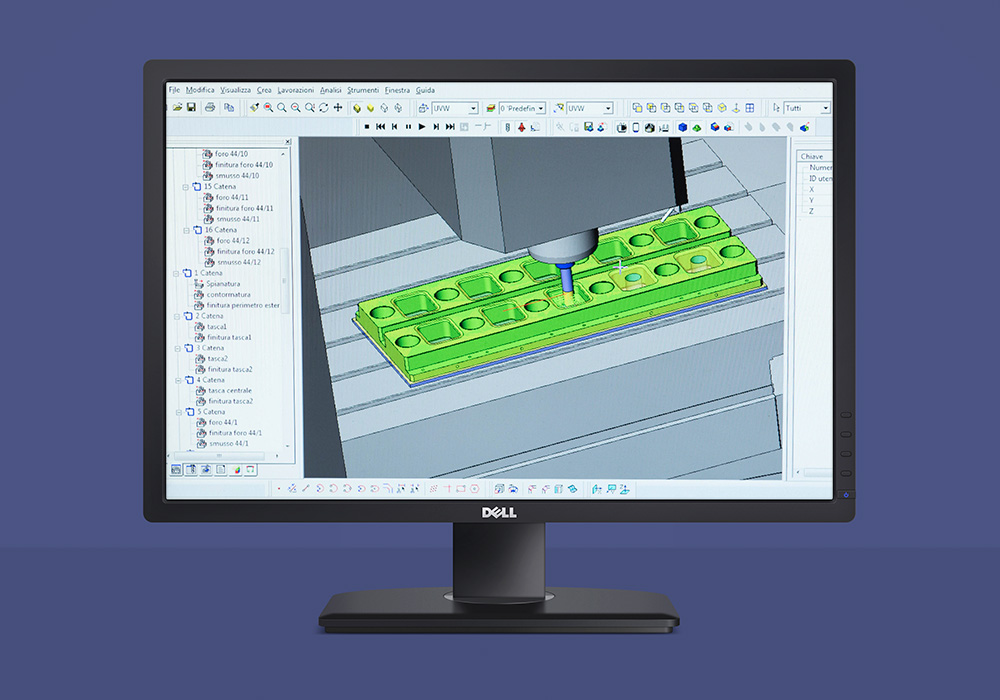

3 - CAD/CAM support

Our programmers further develop the project and create a simulation of the end result with CAD/CAM software.

4 - Production

The operating phase of component creation. Each processing stage is monitored by a dedicated master artisan, guaranteeing a high-quality standard.

5 - Surface treatment

ON REQUEST

We collaborate with outside companies to carry out surface treatments and then finalise the product.

6 - Quality control and delivery

The final phase covers quality control, packing and shipping with custom packaging.